BEHR PREMIUM ADVANCED DECKOVER® Smooth

Featuring EVEN BETTER Adhesion and Cracking Resistance!

The new BEHR PREMIUM ADVANCED DECKOVER® coating resurfaces properly prepared weathered wood and concrete by filling-in cracks and taming splinters, extending the life of your deck and living space so you can enjoy the outdoors. This 100% acrylic formula conceals cracks and splinters up to 6 mm (1/4"). It creates a slip-resistant, waterproof coating that resists cracking and peeling. It's available in 54 solid custom colours, and is great for decks, patios, composite decks, pool decks and walkways.

View ADVANCED DeckOver Colours

DO NOT USE ON DRIVABLE SURFACE SUCH AS GARAGE FLOORS AND DRIVEWAYS.

Finish

Creates a smooth, slip-resistant finish

Best For Use In

For properly prepared exterior weathered or cracked horizontal and vertical wood, concrete and composite surfaces.

Coverage

1st Coat 7 m2 ; 2nd Coat 7 m2

-

Must Prep

Before Use -

2 Coats Required

-

Horizontal

Spread Rate:

1st Coat

7 m2

2nd Coat

7 m2

. -

Clean-Up

Soap & Water

Recommended for properly prepared exterior weathered or cracked horizontal and vertical wood and composite surfaces such as Decks, Railings, Porches and Boat Docks. Also great for concrete surfaces such as Pool Decks, Patios and Sidewalks. Do not use on drivable surfaces such as garage floors and driveways.

Preparation

THE FOLLOWING STEPS AND PRODUCTS ARE RECOMMENDED FOR THE BEST RESULTS.

- All surfaces must be clean, sound, dry and free of any dirt, oil, and grease before application.

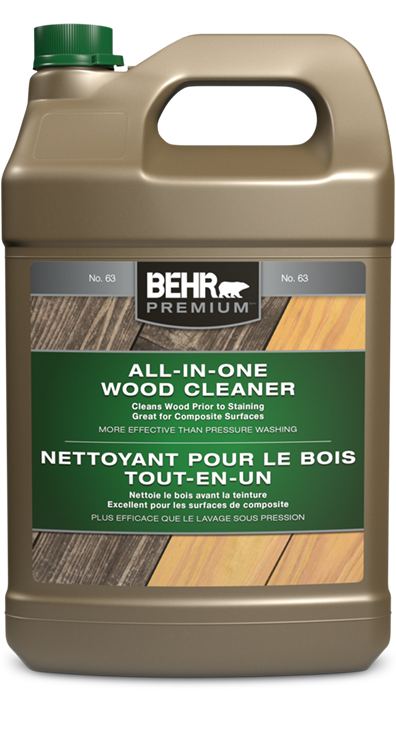

- Wood Surfaces: Replace rotting or unstable boards and remove loose splinters. Remove mildew stains, dirt, oil and grease with a product such as BEHR PREMIUM® NO. 63 All-In-One Wood Cleaner prior to application.

- Use a product such as BEHR PREMIUM NO. 64 Wood Stain & Finish Stripper (must be followed by NO. 63) to remove all loose wood fibers, peeling paint/stain or deteriorated coatings prior to application of DeckOver.

- On new wood, use NO. 63 to remove mill glaze and open the pores of the wood. Rinse thoroughly and allow to dry before coating.

- Concrete Surfaces: Avoid areas that are structurally weak or subject to hydrostatic pressure above 8 psi. Allow new surfaces to cure for 30 days.

- Use a product such as BEHR PREMIUM NO. 992 Concrete & Masonry Paint Stripper to strip peeling coating.

- Use a product such as BEHR PREMIUM NO. 991 Concrete & Masonry Cleaner & Etcher to clean and etch uncoated concrete or NO. 990 Concrete & Masonry Degreaser & Cleaner on sound coated surfaces prior to coating.

Read More

Application

- Use product when air and surface temperatures are between 10-32˚ C.

- During application, avoid exposure of container to direct sunlight. Do not use if rain is expected within 24 hours.

- Intermix multiple containers to ensure colour uniformity.

- Stir product occasionally throughout application. DO NOT THIN PRODUCT.

- FOR NAIL HOLES AND CRACKS UP TO 6 MM, COMPLETELY FILL IN WITH DECKOVER COATING USING A NYLON/POLYESTER BRUSH AND ALLOW TO DRY PRIOR TO ROLLING. DEEP NAIL HOLES AND CRACKS MAY REQUIRE ADDITIONAL FILLING.

- For edges, corners and in between wood boards, apply using a nylon/polyester brush. Use pressure while rolling and apply a generous, even coat using a 1/4-1/2" nap roller. For a smoother texture, use a brush or thinner nap roller (i.e. 1/4").

- For vertical surfaces such as railings, use a nylon/polyester brush or roller and apply two thin coats at a spread rate of 37 m2 (400 sq. ft.) per 3.79 L.

- Airless spray is recommended for experienced applicators only; use a 0.5-0.6 mm tip with 60 mesh filter.

- When spraying vertical surfaces, apply a very thin coat (one pass only) and do not back brush/roll.

- When spraying horizontal surfaces, follow the standard spread rate of 7 m2 (75 Sq. Ft.) per 3.79 L.

- For optimum performance, film uniformity, leveling and to cover cracks, A SECOND COAT MUST BE APPLIED.

- Maintain a wet edge when applying.

Read More

Dry Time

- 4-6 hours before recoat. Dries to touch in 4 hours.

- Wait 24-48 hours before light foot traffic. 72 hours to full cure.

- Additional dry time may be needed in cooler temperatures and higher humidity.

- Premature heavy traffic will cause coating failure.

Read More

Disposal

- For disposal of empty containers and unused product, contact your household refuse collection service.

Read More

To consult with a Behr Certified Coatings Professional, call 1-800-661-1591.

Read More

Read More

Reviews

Often Bought Together

How-To

Find step-by-step instructions in our how-to articles and videos.

SDS AND DATA SHEET

WARRANTY

For one year from the date of purchase, Behr Process LLC warrants to the original consumer purchaser, (1) that the product meets Behr Process LLC’s manufacturing specifications, and (2) the performance of this product when applied according to the label instructions and specifications. In the event this product proves to be defective within one year from the date of purchase, Behr Process LLC will, at its option and upon presentation of proof-of-purchase (the original receipt), either furnish an equivalent amount of new product or refund the original purchase price of this product to you. The clause of limitation of liability which follows is inapplicable in Québec. This warranty excludes (1) labour and costs of labour for the application or removal of any product, and (2) any incidental or consequential damages, whether based on breach of express or implied warranty, negligence, strict liability or any other legal theory. To the extent permitted by applicable law, any implied warranties including the implied warranties of merchantability and of fitness for a particular purpose, are limited to the duration of this express warranty. The above provisions are not intended to operate where prohibited by law. This limited warranty is the only warranty provided by Behr Process LLC unless extended by a provincial consumer statute. To obtain warranty service, call 1-800-661-1591, or contact Behr Process LLC at 110-600 Barlow Square S.E., Calgary, AB T2C 5T7. Behr Process LLC reserves the right to inspect any and all application of the product prior to processing your claim made under this warranty.